What is Cast Iron?

Cast iron is a special mix of metals that contains mainly iron and carbon. The amount of carbon is important – usually between 2% and 4%. This is more carbon (C) than steel, so cast iron behaves differently. Other elements like silicon (Si) (0.5-3%), manganese (Mn) (0.2-1%), and small amounts of phosphorus (P) and sulfur (S) are also present. Think of it like a recipe – changing even small amounts of these ingredients can create different cast iron types.

Have you ever noticed how some cast iron items are harder than others?

The secret is in the mix of elements.

Understanding Cast Iron\’s Inner Structure:

When we look at cast iron under a microscope, we see interesting patterns. The main things we see are:

- Small crystal areas

- Sometimes, hard particles

- Carbon pieces (called graphite)

- The metal background (called the matrix)

The way these parts arrange themselves determines how the cast iron will behave. It\’s like looking at a tiny city map where every building and street has a purpose.

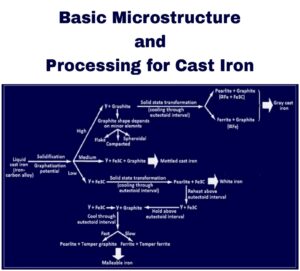

How Carbon Makes Different Structures..?

Carbon is the most important element in cast iron because it can form two main shapes:

- Graphite flakes – look like tiny dark lines

- Iron carbide – forms hard, white areas

The amount of silicon helps decide which form the carbon takes. More silicon (above 1%) helps create graphite flakes, while less silicon often leads to iron carbide. This is why adding silicon is one of the main ways we control cast iron\’s properties.

Types of Cast Iron Based on Structure:

Gray Cast Iron

In grey cast iron, the carbon forms flat flakes. Under a microscope, these flakes look like dark lines on a lighter background. The background can be:

- Pearlite (a striped pattern)

- Ferrite (plain light areas)

- Sometimes both

The flakes help grey cast iron:

- Easy to machine

- Transfer heat well

- Reduce vibrations

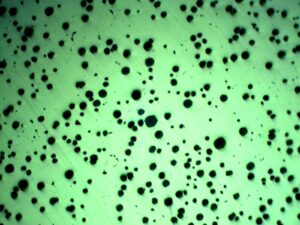

Ductile (Nodular) Cast Iron

Did you know that the shape of carbon in cast iron can be changed by adding small amounts of magnesium?

When we add a small amount of magnesium (about 0.04%), something interesting happens – the carbon forms round balls (Nodules) instead of flakes. These nodules make the cast iron stronger and more flexible. The background structure can still be pearlite or ferrite, affecting how hard or soft the final product is.

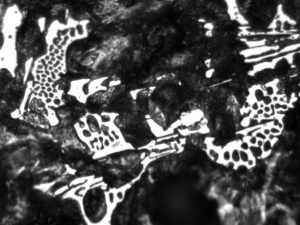

White Cast Iron

In white cast iron, we see no graphite at all. Instead, the carbon stays trapped in iron carbide, which forms hard, white areas. This happens when:

- The iron cools quickly

- There isn\’t much silicon

- The chemistry is controlled carefully

The Importance of Cooling Rate

How fast cast iron cools affects its final structure. Think of it like making ice – fast freezing makes small crystals, while slow freezing makes large ones.

In cast iron:

- Slow cooling often makes grey cast iron

- Fast cooling usually makes white cast iron

- Medium cooling can make mixed structures

Can you guess why a thick casting might have different properties than a thin one?

How Heat Treatment Changes Structure:

After cast iron solidifies, we can heat it again to change its structure. Different temperatures create different results. We can break down iron carbide and can make a softer casting. Cooling speed also controls the final hardness.

Understanding Composition Effects

Each element in cast iron has a job:

- Carbon (2-4%): Forms either graphite or carbides

- Silicon (0.5-3%): Helps graphite form

- Manganese (0.2-1%): Controls hardness

- Phosphorus (0.05-0.2%): Helps the iron flow when liquid

- Sulfur (0.02-0.25%): Affects how graphite forms

Structure and Properties Connection…

The way cast iron behaves depends on its structure:

- Flake graphite makes it good for dampening vibrations

- Round graphite makes it stronger

- Iron carbide makes it wear-resistant

- Background structure controls hardness

Making Better Cast Iron…:

To make good cast iron, we need to control:

- How fast it cools

- The mix of elements

- Any heat treatment after cooling

- The temperature during processing

Each of these affects the final structure and properties.

Practical Uses Based on Structure…:

Different structures work best for different jobs:

- Flake graphite for engine blocks

- Round graphite for tough parts

- White iron structure for wear resistance

Understanding the structure helps us pick the right type for each use.

Looking Inside Cast Iron…:

When we examine cast iron\’s structure, we look for:

- Any unusual areas

- Graphite shape and size

- How the graphite is spread out

- What the background looks like

These tell us how the cast iron will perform.

So overall, cast iron\’s useful properties come from its special structures inside. By controlling the composition and processing, we can make cast iron that works well for many jobs. Whether we need something hard, strong, or good at handling heat, understanding the structure helps us make the right choice.

Do you know which material is best for cylinder liners..?

Let\’s, give us a chance to help you to choose the right material for your product.